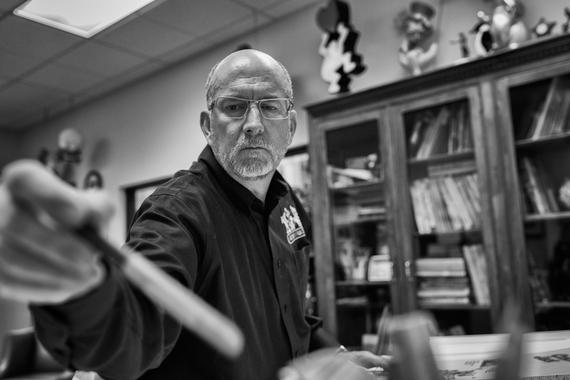

The Macy's Thanksgiving Day Parade balloons have been riding high since 1927 when Felix the Cat first took to the skies. As a kid I was fascinated by how these enormous titans were flown through the the narrow streets of NYC, and now as an adult I am fascinated by how they are created. VP of Macy's Parade Studios, John Piper was kind enough to give me an behind the scenes look at the making of these holiday icons. Enjoy the photos!

Shameless plug for my NYC photoblog ALL THE LONELY PEOPLE: Instagram, Facebook, Twitter. If you're doing something cool and NYC ping me and I'll come shoot you!

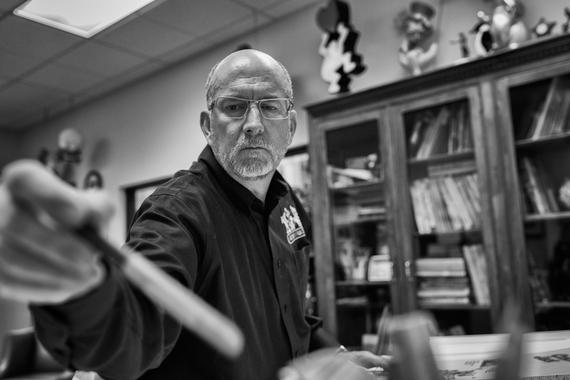

VP of Macy's Parade Studio John Piper

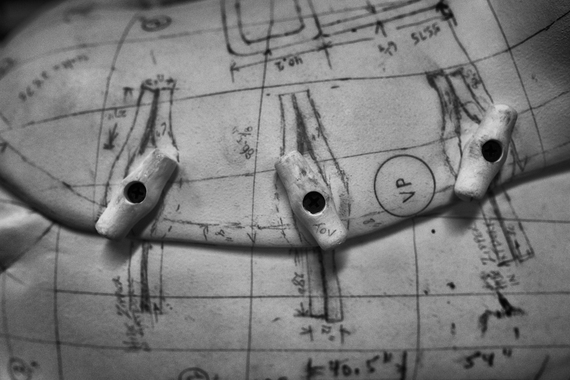

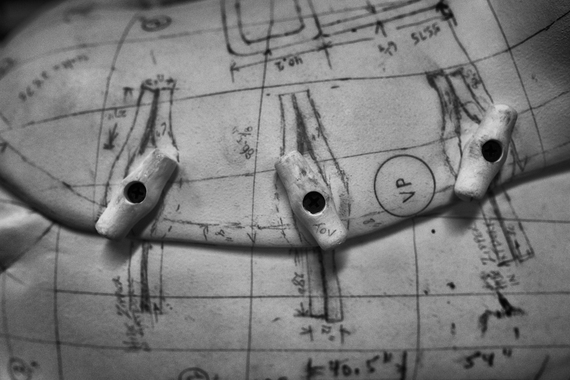

All of Macey's Parade balloons begin as sketches and clay models.

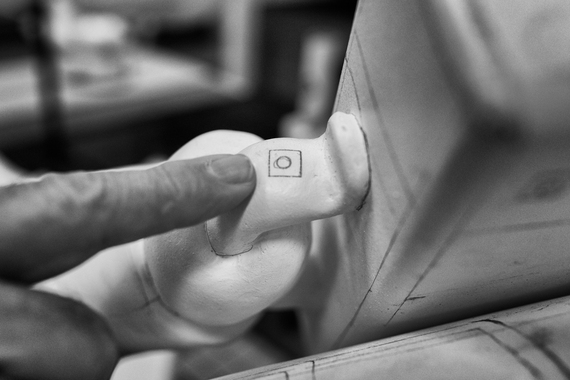

Clay model for Macey's Spiderman balloon.

Clay model hand for Macey's Spiderman balloon.

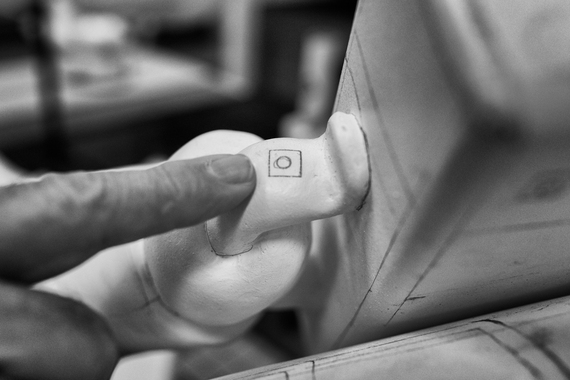

After the clay model is complete, a mold is made and a set of plastic cast models are produced. Here is a plastic cast model for the new Paddington Bear ballon.

The plastic cast models are then drawn upon to denote everything from ballon dimensions to paint colors.

The plastic casts are drawn upon to denote how the rubber will be cut into sections to form the final ballon.

And of course they have to figure out where to inflate the balloon.

The final plastic cast model for the new Paddington Bear balloon.

Other versions of the plastic cast models are painted in exacting detail.

John Piper examines the painting detail on the final plastic cast model for the new Paddington Bear balloon.

John Piper keeps a model human on standby to check the scale of the plastic cast model.

After the cast models are mapped, the rubber sections measured and cut to form.

A Macey's Parade Studio production artist then glues the sections of rubber together with adhesive.

The Macey's Parade Studio signature adhesive is carefully painted onto the seams.

Each crease is carefully matched together by hand.

Each crease is then pressed firm with a roller to get all the air out of the seam.

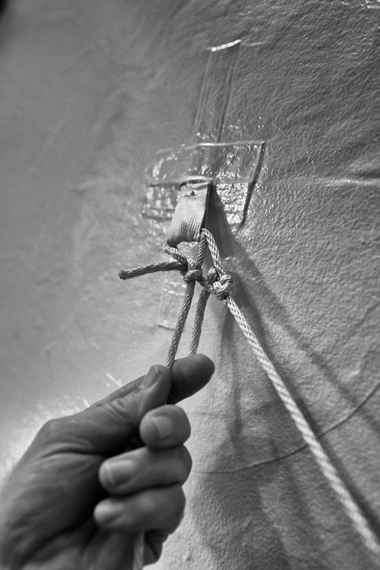

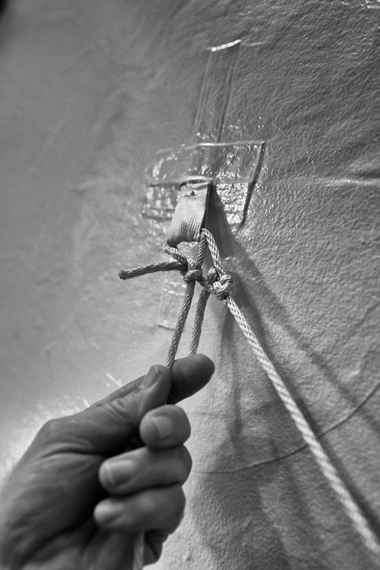

All the balloon holder attachments are then affixed and tested in the workshop.

Once the first assembly is complete, they blow up the ballon to test it in the studio. John Piper is seen here with another studio production artist checking the new Pillsbury Doughboy balloon against it's final plastic cast model.

After being glued, tested and painted the balloons travel to Citi Field in Queens where they have their first test flight just a few weeks before the parade.

The scale of the construction and the level of painted detail is astonishing. It really makes you feel like a kid again.

The new Paddington Bear ballon on its inaugural flight.

The balloons average 25 handlers, all of them Macey's employees.

The new Paddington Bear ballon on its inaugural flight.

One of the Macey's employees taking the reins on Padding Bear's inaugural flight.

The new Paddington Bear ballon on its inaugural flight.

Each ballon is anchored onto a motorized cart at its midline.

Each ballon is anchored onto a motorized cart at its midline.

The new Paddington Bear ballon on its inaugural flight.

After the parade, the balloons are stored in bins and bags back at Macey's Parade Studios.

After the parade the balloons are stored in bins and bags back at Macey's Parade Studios.

Bin designated for the Ronald MacDonald Macey's Thanksgiving Day Parade balloon.

Support HuffPost

Our 2024 Coverage Needs You

Your Loyalty Means The World To Us

At HuffPost, we believe that everyone needs high-quality journalism, but we understand that not everyone can afford to pay for expensive news subscriptions. That is why we are committed to providing deeply reported, carefully fact-checked news that is freely accessible to everyone.

Whether you come to HuffPost for updates on the 2024 presidential race, hard-hitting investigations into critical issues facing our country today, or trending stories that make you laugh, we appreciate you. The truth is, news costs money to produce, and we are proud that we have never put our stories behind an expensive paywall.

Would you join us to help keep our stories free for all? Your contribution of as little as $2 will go a long way.

Can't afford to donate? Support HuffPost by creating a free account and log in while you read.

As Americans head to the polls in 2024, the very future of our country is at stake. At HuffPost, we believe that a free press is critical to creating well-informed voters. That's why our journalism is free for everyone, even though other newsrooms retreat behind expensive paywalls.

Our journalists will continue to cover the twists and turns during this historic presidential election. With your help, we'll bring you hard-hitting investigations, well-researched analysis and timely takes you can't find elsewhere. Reporting in this current political climate is a responsibility we do not take lightly, and we thank you for your support.

Contribute as little as $2 to keep our news free for all.

Can't afford to donate? Support HuffPost by creating a free account and log in while you read.

Dear HuffPost Reader

Thank you for your past contribution to HuffPost. We are sincerely grateful for readers like you who help us ensure that we can keep our journalism free for everyone.

The stakes are high this year, and our 2024 coverage could use continued support. Would you consider becoming a regular HuffPost contributor?

Dear HuffPost Reader

Thank you for your past contribution to HuffPost. We are sincerely grateful for readers like you who help us ensure that we can keep our journalism free for everyone.

The stakes are high this year, and our 2024 coverage could use continued support. If circumstances have changed since you last contributed, we hope you’ll consider contributing to HuffPost once more.

Already contributed? Log in to hide these messages.