From ultraportable drones to solar-powered water heaters to smart earplugs, today's coolest technologies start with amazing parts. Through the power of digital manufacturing, entrepreneurial product designers are finding it much easier to get the parts they need. Popular manufacturing methods, like CNC machining, 3D printing and injection molding, all benefit from the digitization of manufacturing.

Digital manufacturing automates much of manufacturing's initial nonrecurring engineering steps. In doing so, it can significantly reduce costs and accelerate the research, design, testing and production of new parts. Consider this: The time between placing an order and getting parts using traditional manufacturing processes can be two to three months or more, with tooling costs as high as $80,000. The technology-enabled processes of digital manufacturing can produce the same part in as fast as a day at a fraction of that cost. These savings fuel innovation and help entrepreneurs get their products to market faster.

Here are four tips to help you turn your next innovative idea into a professional product using digital manufacturing.

1. Don't Go Overseas

A common mistake among entrepreneurs is that they put too much stock in per unit costs and not enough in total production costs. Doing so leads them to spending countless hours sourcing manufacturing partners in China. There are two big, frequently overlooked factors that should be considered when calculating total production costs:

- Inventory costs: Many traditional manufacturers have high, minimum-order volumes - often hundreds of thousands of parts or more. In many cases, that's more parts than are needed, especially in early stages of a product introduction. During the rush of launching a new product, it's easy to overshoot production estimates, and the cost of carrying inventory (storage) and write-offs (excess inventory) can be significant. When demand is unpredictable, which is often the case in the beginning, produce and store lower quantities to reduce your financial risks.

- Prototyping efficiencies: Although you might think about skipping the prototyping phase because it will add costs and time to your product development, think about the risks you could minimize or potentially eliminate by optimizing your design prior to jumping into production. The way to do prototyping efficiently and cost-effectively is to find a manufacturing partner that will provide you with manufacturability analysis and feedback early on and often during the prototyping phase. That's exactly what digital manufacturers do - and you can find a good partner right here at home.

2. Know How the Product Life Cycle Impacts Manufacturing

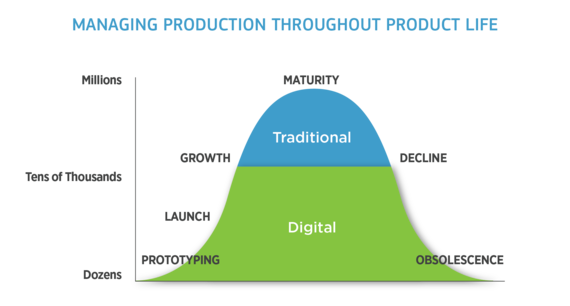

Products progress through fairly consistent life stages. Understanding digital manufacturing's role in each stage of the product life cycle will speed up product design while keeping costs down.

- Prototyping: This process is essential to early product development, as it allows designers to test and improve their designs before going to market. Digital manufacturing provides a competitive advantage during the prototyping phase, allowing for immediate design analysis and feedback, and affordable prototyping, as well as accelerated prototype cycles.

3. Understand the Benefits of Each Manufacturing Technology

Digital manufacturing is a process that is used with a growing number of manufacturing technologies, including 3D printing, rapid injection molding and CNC machining. Each technology serves a distinct purpose; from very early prototyping with concept models; to form, fit and function testing; to short-run production that bridges the gap to large-scale manufacturing.

Understanding the why and the what of the three most popular digital manufacturing technology categories will improve your product design and save you a lot of time:

- 3D Printing: The additive process works great for intricate designs, multipart assemblies and rapid prototyping. In some instances, 3D printing can also be used to build functional, end-use parts in low quantities. Four primary methods include stereolithography (used for thermoplastic-like parts), selective laser sintering or SLS (for industrial-grade nylon components), direct metal laser sintering or DMLS (for dense metal production), and fused deposition modeling (FDM).

4. Find a Technology-Agnostic Manufacturing Partner

No digital manufacturer offers every type of manufacturing technology. While some providers specialize in one, others offer a breadth of technologies. Your best bet is to find a partner that has a powerful software system, has a broad set of manufacturing options, and is set up to scale with you throughout the life of your product. Doing so will provide more design and production flexibility, saving you time, money and headaches.

Digital manufacturing offers a unique value proposition: It lowers production costs and accelerates time-to-market by automating much of the front-end of the manufacturing process. The next time you have a great idea for a new product, find ways to weave digital manufacturing into your production process.